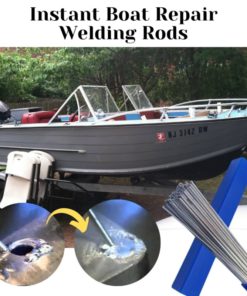

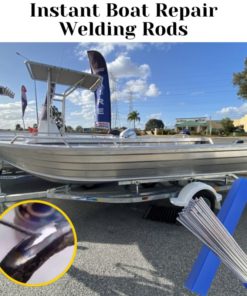

Instant Boat Repair Welding Rods

$17.90 – $46.90

Instantly Weld Repair Your Boat With Ease!

You can repair aluminum boat with the product we offer you

The product containing aluminum oxide in it is strongly adhered to aluminum

The strongest, fastest, and easier way to weld repair your boat with these boat repair welding flux rods!

The Aluminum brazing is very simple and convenient

Repaired aluminum won’t break again and won’t cost you much

Easy To Use

1. BRUSH WELL: Simply clean the area you’re about to weld by brushing until it becomes shiny

2. HEAT WELL: Evenly heat the area to be welded

3. FILL IN: As you heat, rub the rod vigorously against the heated area until the rod starts flowing.

OUR GUARANTEE

Customer satisfaction is very important to us. That’s why we recommend innovative products we can find to ensure that you are always satisfied when shopping from us.

If for any reason you are not satisfied with us, please write to our email address or call us . We will do everything we can until you are 100% satisfied with us

Buying products online can be daunting for you, but considering we’re living in the 21st century, that’s just normal.

AN AMAZING CAUSE

We are proud to support the The Children’s Defense Fund (CDF), which has always helped children.

Note: Delivery of Promotional Items may take 10-14 working days due to the high number of orders.

James F. –

Probably the most useful electrodes ive ever purchased. I do a lot welding on thin tube mild steel that is usually slightly rusty or covered in millscale. It cuts through this with ease which is a huge benefit in prep time. Thin mild steel tubing is structurally solid, cheap but some of the most frustrating material to weld. With .060 wall thickness tube, its almost impossible not to blow through the work piece. I found these rods to be the most forgiving in this aspect while still fully penetrating. I can also make significantly longer welds without allowing the piece to cool. Running them on non-digital welder so cant tell you exact amps but its between 58 and 63. I can also leave these in my tool box for weeks and they run as good as new. No moisture sensitivity or storage limitations.

Justin S. –

I have used these on 3/32 to 1/8 tube and square tube up to 1/8″ angle iron in DCEP mode at around 50 A with pleasing performance. I turned down to 35 A to tack casters on a metal base. (Why bolt them!). The casters are 1/16″ mounting plates and focusing most of the heat on the 1/2 steel substrate, i was able to weld them nicely without burning through the mounting plate. I’ve always like Forney rods period!